How to purchase high quality outdoor full-color SMD lamp beads

With the development of LED display market, full-color SMD lamp beads will gradually become the mainstream luminous devices for outdoor display screens in the future.In the outdoor environment, for the stable use of SMD lamp beads, high reliability and high performance are the prerequisites.How to identify and select high quality outdoor full-color SMD lamp beads?Is there a complete set of criteria?

Advantage analysis of full-color SMD lamp beads:

Compared with the traditional straight oval lamp bead represented by 346, the SMD lamp bead has three advantages:

1. In terms of performance, SMD lamp beads have advantages such as large Angle, good mixing light and good consistency;

2. From the perspective of structure, SMD lamp bead can be applied to all kinds of small spacing screens, and the screen structure produced by SMD lamp bead is light, convenient for transportation and installation;

3. From the perspective of production, the production and processing of SMD lamp beads are of high automation and better machining accuracy, which can greatly improve the production efficiency.

I. how to guarantee the high reliability of outdoor full-color SMD lamp beads

1. How many links are there in the use of LED lamp beads?

The high reliability of LED lamp bead means that it can maintain the stability of quality in the whole process of customer use.The use of LED lamp beads can be divided into several parts.The first is factory inspection. After passing the final inspection and electric performance test in the production factory, the package is delivered.Next is the transport and storage link, after transport, storage and other links to reach the display factory;Then is the production processing link, the screen factory opens the package, through the production process such as the upper board and welding, completes the display screen finished product production processing;Finally, normal operation.During this whole process, the LED lamp bead must work reliably, cannot appear dead light phenomenon.During this period, LED beads should be able to withstand the impact of tidal expansion and temperature, especially the welding temperature impact with the maximum temperature of 260 degrees.LED lamp beads are composed of a variety of different materials, such as copper, resin, PPA, conductive adhesive, luminescent chip, etc., and their moisture absorption coefficient and temperature expansion coefficient are different, so the material cooperation between them is quite critical. Otherwise, dead lamps will appear.Therefore, the reliability of LED lights must be judged by simulating the use process of LED lights.The following is an LED reliability model based on the IC simulation model of semiconductor industry.

2. How to simulate the transportation, storage and launch of customers?

Take a certain amount of product through the following experiment, and evaluate its test results.

Finish 120 degree 24-hour baking: the purpose is to remove the influence of residual moisture, as preparation for simulation experiment.

Shock cycle high and low temperature impact: the purpose is to simulate the temperature impact in transportation and storage after delivery.The choice of high and low temperature depends on the product grade.

Humidity resistance experiment (wet-resistance experiment) is stored in a certain temperature and humidity environment. The aim is to simulate the wet-resistance of products before they are delivered to welding.Temperature, humidity and time of product moisture resistance grade.

Maximum temperature of 260 degrees for 3 reflow solders: to simulate the welding process.

The test of strain requires that none of the products have any electrical performance problems.

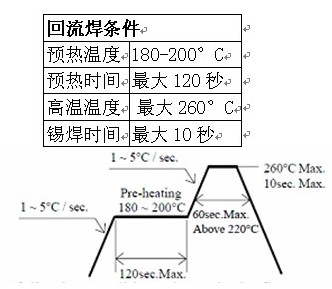

Conditions for reflow soldering:

1

Note: the above is just a simulation of the production process of the PCB board of the product, which has not involved the process of product use, but has been faced with two selection problems of temperature and humidity.

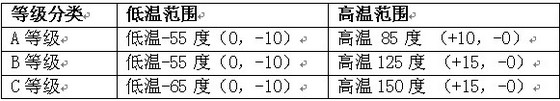

3. How to select high and low temperature impact grade of full-color SMD lamp beads?

In the integrated circuit industry, it can be generally divided into 11 levels. For LED products, three levels can be selected, as shown in the following table:

2

Note: class A/B is recommended for indoor use and class C for outdoor use.

4. How to choose the moisture resistance level of full-color SMD lamp beads?

Generally, the anti-humidity level is divided into 7 grades. The requirements of anti-humidity test are shown in the following table:

3

4

The moisture resistance level is mainly affected by the packaging materials and the customer open packaging to the residence time between reflow soldering.Humidity indicator CARDS should have at least 5%, 10% and 60% of the three indicators or color - changing silica gel indicators.If after opening the package indicator or silica gel discoloration indicates that the product is damp, it must be baked to save the product.The baking conditions are 125 degrees for 16 hours or 90 degrees for 48 hours.

5. How to verify the service life of outdoor full-color SMD products?

The product life can be simulated through high and low temperature test (TC) to the simulator.High and low temperature test conditions are consistent with the above high and low temperature impact test. 3 grades can be selected, as shown in the following table:

5

Note: class A/B is recommended for indoor use and class C for outdoor use.

High and low temperature cycle requirements:

6

High and low temperature cycles can be divided into 200 cycles, 500 cycles and 1000 cycles.The number of cycles can be equated to the length of service life.

6. How to verify the air tightness of outdoor full-color SMD lamp beads?

Experiment on waterproof and damp proof ability.The experimental condition is that the LED lamp is cooked at 121 degrees, 100% humidity and 2 atmospheres.See the following table for details:

7

7. How to verify the anti-salt spray corrosion ability of outdoor full-color SMD lamp beads?

LED screens are subject to corrosion such as acid rain when used outdoors, so they have to be tested by salt spray.

Test conditions are: light on PCB, glue over the light foot, protect the light foot, in 5% sodium chloride brine solution, solution PH adjustment in neutral range (6.5 ~ 7.2) as a spray solution, test temperature 35 ℃, require salt fog sedimentation rate in 1 ~ 3 ml / 80 cm2. H, between subsidence are generally 1 ~ 2 ml / 80 cm2. H.No dead light after 500 hours.

Conclusion:

High reliability products must pass all of the above tests and are at the highest level. Dead lights are not allowed.

2. How to reflect the high performance of outdoor full-color SMD products

The high performance of the so-called outdoor full-color SMD products is the highlight of other products other than reliability to meet more customer demands and improve the selling point of the whole screen, which can be reflected from the following aspects:

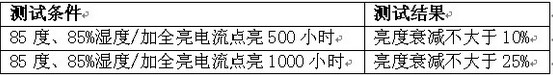

1. How to conduct the aging attenuation test of outdoor full-color SMD lamp beads?

2. How to test the UV resistance of outdoor full-color SMD lamp beads?

8

9

3. Appearance features of outdoor full-color SMD products:

3.1 surface matte technology:

The surface does not reflect light and does not reflect light under strong light irradiation, so that the contrast is higher, the image is more complete, and external light interference is reduced.

10

3.2 high-contrast technology:

High contrast products make the image more colorful and colorful.This technology is more suitable for use on stage, TV station, large performance background, etc.

11

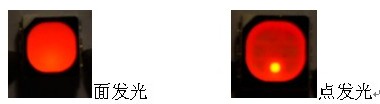

3.3 surface luminescence technology:

Face luminescence is red, green, and blue light that glows on the whole face rather than at points.It can make screen images softer and more ergonomic, and long viewing does not harm the eyes, especially close viewing.

12

3.4 low pin technology:

The height of the pin is only 1.2mm, which can reduce the difficulty of pouring glue for the display manufacturer, so as to better protect the lamp foot and increase the service life.

13

Conclusion:

High quality outdoor full-color SMD lamp beads must have high reliability and high performance.In combination with the real condition of the use of LED electronic display screen, through the practice has proved that this set of outdoor full-color SMD lamp beads have very high standards of reliability test is scientific and practical, advice can be reference to the relevant manufacturer standard selection and test and verify the reliability of outdoor full-color SMD lamp beads, thus safeguarding SMD lamp beads can be stable in the field of outdoor applications.

.jpg)