LED beads production technology and production process

Time:2018-11-24

Views:165

How are led beads made?This paper gives readers a detailed explanation of LED chip inspection, LED expansion, glue dispensing, glue preparation, pressure welding and other LED production processes and production processes.

1.LED chip inspection

Microscopic examination: whether there is mechanical damage and pitting on the material surface (lockhill chip size and electrode size meet the requirements of the process) whether the electrode pattern is complete.

LED chip manufacturing process

LED chip manufacturing process

2. LED expanding slice

Since LED chips are still closely arranged and spaced (about 0.1mm) after chip cutting, it is not conducive to the operation of the following procedures.We use the chip expander to expand the film bonding chip, and the spacing of LED chip is stretched to about 0.6mm.Manual expansion can also be used, but it is easy to cause chip drop waste and other adverse problems.

3. LED dispensing

Put silver glue or insulating glue on the corresponding position of LED bracket.(for GaAs, SiC conductive substrates, red, yellow, yellow and green chips with back electrode, silver glue.Blue and green LED chips with sapphire insulating substrate are fixed with insulating adhesive.

The difficulty of the process lies in the control of the amount of glue dispensing, and there are detailed process requirements in the height and position of the glue dispensing.Due to the strict requirements of silver glue and insulating glue in storage and use, the waking material, stirring and service time of silver glue must be paid attention to in the process.

4. LED for glue

In contrast to glue dispensing, glue dispensing machine is used to coat silver glue on the back electrode of LED, and then install the LED with silver glue on the back on the LED bracket.The efficiency of glue preparation is much higher than that of glue dispensing, but not all products are suitable for glue preparation process.

5. Manual LED stinger

The expanded LED chip (with or without glue) is placed on the fixture of the bayonet table. The LED bracket is placed under the fixture. Under the microscope, the LED chip is punctured to the corresponding position one by one with a needle.Compared with automatic mounting, manual mounting has the advantage of changing different chips at any time, which is suitable for products that need to install multiple chips.

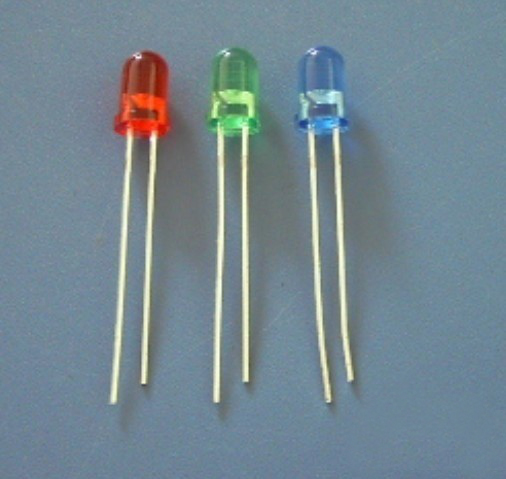

LED lights,

6.LED automatic mounting

Automatic mounting is actually a combination of adhesive (glue) and chip installation two steps, the first point on the LED bracket silver glue (insulation glue), and then vacuum nozzle will be LED chip moving position, and then placed in the corresponding bracket position.In the process of automatic mounting, it is necessary to be familiar with the operation programming of the equipment and adjust the adhesive and installation precision of the equipment at the same time.In the selection of nozzle as far as possible to choose bakelite nozzle, to prevent damage to the surface of LED chip, especially blue, green chip must use bakelite.Because the nozzle will scratch the current diffusion layer on the chip surface.

7. The LED sintering

The purpose of sintering is to solidify the silver glue, and the sintering requires monitoring the temperature to prevent batch defects.Silver glue sintered at 150 ℃, the temperature of the general control sintering for 2 hours.According to the actual situation can be adjusted to 170 ℃, 1 hour.Insulated generally 150 ℃, 1 hour.

Silver glue sintering oven must be opened every 2 hours (or 1 hour) according to the requirements of the process to replace the sintered products, the middle shall not be opened at will.Sintering oven shall not be used for other purposes to prevent pollution.

LED bonding 8.

The purpose of pressure welding is to lead the electrode to the LED chip and complete the connection of internal and external leads of the product.

LED pressure welding process has golden wire ball welding and aluminum wire pressure welding two kinds.The right picture is the process of aluminum wire pressing and welding. First, press the first point on the LED chip electrode, then pull the aluminum wire to the top of the corresponding bracket, press the second point and then tear the aluminum wire.Gold wire ball welding process before pressing the first point to burn a ball, the rest of the process is similar.

Pressure welding is a key link in LED packaging technology, the main need to monitor the process is the pressure welding of gold wire (aluminum wire) arch wire shape, solder joint shape, tension.

9. The LED sealant

LED packaging is mainly a little bit of glue, sealing, molding three.Basically the difficulty of process control is bubble, much lack material, black spot.The main design is the selection of materials, the choice of good combination of epoxy and bracket.(general LED cannot pass air tightness test)

9.1 LED dispensing

TOP-LED and Side-LED are suitable for adhesive packaging.Manual dispensing packaging requires a high level of operation (especially white LED), the main difficulty is to control the amount of dispensing, because epoxy will thicken in the process of use.The point glue of white LED also has the problem that phosphor powder precipitation leads to light chromatic aberration.

9.2LED filling and sealing

Lamp-led is encapsulated in the form of encapsulation.The filling and sealing process is to inject liquid epoxy into the mold cavity of LED molding first, then insert the pressed welded LED bracket, put it into the oven to solidify the epoxy, and then remove the LED from the mold cavity to form.

9.3LED die packaging

Put the pressed and welded LED bracket into the mold, use the hydraulic press to close the upper and lower two sets of molds and vacuum them, put the solid epoxy into the inlet of the glue injection channel, heat it with the hydraulic jacking rod and press it into the mold glue channel, and then the epoxy enters into each LED forming groove along the glue channel and solidifies.

10.LED curing and post-curing

Curing is refers to the encapsulation of epoxy curing, general epoxy curing condition at 135 ℃, 1 hour.Moulded packaging is in commonly 150 ℃, 4 minutes.Post-curing is to allow epoxy to fully solidify and thermal aging of LED.Post-curing is very important to improve the adhesion strength between epoxy and PCB.General conditions of 120 ℃, 4 hours.

11.LED bar cutting and chip cutting

Since leds are connected together in production (not a single one), Lamp encapsulated leds use cutting bars to cut off the connecting bars of LED scaffolds.Smd-led is on a PCB board, which requires a chip cutter to complete the separation work.

12. The LED test

Test the photoelectric parameters of LED, check the appearance size, and select LED products according to customer requirements.

13. The LED packaging

Count and package finished products.Ultra bright LED needs anti - static packaging.

PS:

School auditorium, company conference room indoor led display can be selected model:

P2.5led display /P3led display /P4led display /P5led display

分享

.jpg)